Do you know how to choose the right Wood Grades (Yes, They Exist!)

Why should you care about this? When it comes to hardwood floors, the term "wood grade" will likely come up in the installation project and there are a number of different ones. Different wood grades translate into distinctive appearance characteristics and variations of colours. When shopping for hardwood floors, an informed homeowner needs to understand the relationship between the wood grades, their qualities and functions so that he/she can make a wise decision.

1. How a wood floor is graded?

There are a number of factors involved in grading wood, which are:

- Knots: Their number and size

- Sap: Its amount present in the wood

- Colour variations

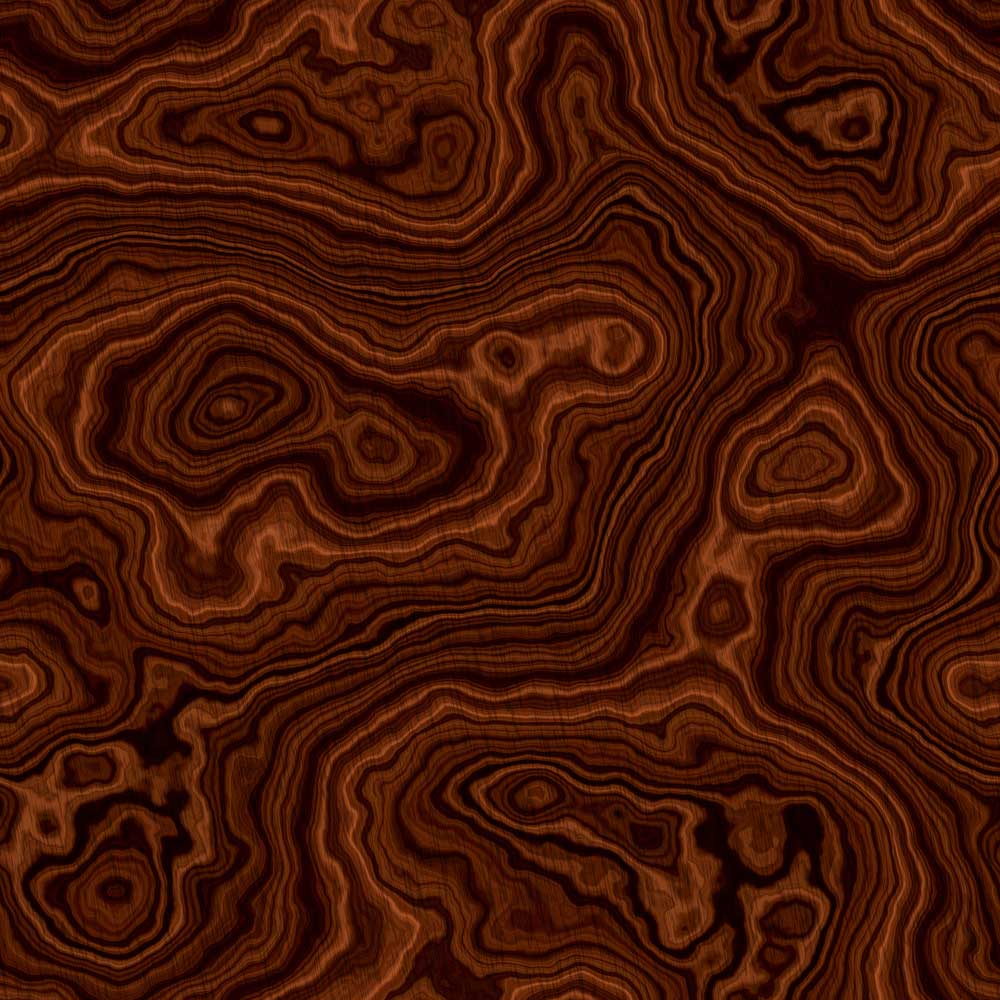

- Grains: their length and patterns.

It is interesting to note that how the grain patterns appear depend on how the flooring was cut from the tree itself. The cutting technique will also affect the hardwood's stability and price.

- Plainsawn, the most common cut, brings about great variations in grain patterns.

- Quartersawn creates a relatively more uniform grain patterns as this techniques makes the wood twist and cup less. The log is cut into quarters before strips of woods are made to form hardwood flooring planks.

- Riftsawn flooring also exhibits uniformity in grain patterns as this cut's angle is only slightly different than that of Quartersawn. Riftsawn flooring boards are reported to have higher stability and quality, hence, they are more expensive than planks cut with the other methods.

The list of factors involved in the wood grading process is not exhaustive. Generally speaking, the smaller the knots, the lower the amount of sap. This leads to a better uniformity of colour, which translates into a higher wood grade. The higher grade the wood has, the more expensive it is.

There is reportedly no universal hardwood grade codes, but there are certain common terms hardwood floor manufacturers use. It would be beneficial for your quest of an ideal hardwood floor if you get familiar with the wood grade terms.

2. The commonly seen wood grades

- Clear grade (also known as FAS – firsts and seconds): This is the best grade of hardwood floors on the list. Cut from the center of the log, the its appearance is clear. Clear-grade hardwood floors have unvaried board lengths, on which knots or pinholes are very small and barely visible to almost invisible. The visible knots tend to be small and unobtrusive. It is "Clear" grade in the sense that its main characteristics are the most uniform appearance and patterns with minimal color variation.

- Select and Better grade (also referred to as AB grade): This grade is slightly lower than Clear grade. It is recognized by the limitation of character marks, knots and pinholes. Staining, checking, and mineral streaks that cause variance are not detected in Select and Better wood grade. Uniform in color and length, the surface of the plank will achieve the cleanest presentation within the species after being finished

- #1 Common grade (also called Natural grade/ 2nd grade): The next-best grade has more coloring variations and greater length variation. Hardwood flooring boards of this grade have shorter length and are more likely to have the following defects: dime-size broken knots, season and kiln checks, and small worm holes. Minor imperfections can be properly filled and finished and will not affect the floor's performance. Note that 1# Common wood grade boards will contain characteristics depending on the wood species. Gaps of no more than 0.031" should be seen when assembling #1 Common grade wood flooring boards.

- #2 Common Grade (also known as Rustic grade/ 3rd grade): With an increase in visible knots and pinholes, #2 Common Grade also has shorter board length. Homeowners who are fond of rough hardwood floors, who don't mind the color variations, some defects in grain patterns and the rustic character will be happy with this wood grade. In fact, a beautiful-looking patchwork effect is achieved when 2# Common grade wood boards are put together, thanks to its wide variations in dark to light colours. A similar expectation in gap exhibition between #2 Common grade flooring boards is similar to that of #1 Common Grade.

- Cabin grade (also referred to as Tavern grade): This grade might include some low-grade wood characteristics, like open knots, cracks, or splits. Upon installation, certain quality imperfections are more likely to come up, such as damaged marks visible from milling process. Cabin grade has shorter board lengths, small dings, and more coloring variations, which might require more efforts in assembling to achieve a pleasing look than other wood grades, like putting together pieces of puzzles. Thus, expect a greater amount of wastage (order 10-20% more than you need) and make sure the planks are sorted through before installation. Because of the allowed quality defects, flooring made of this wood grade often don't go with structural warranty. However, a warranty on the finish is usually available. Wood floors of Cabin grade are suitable for low-investment projects as it is much cheaper than others. Cabin grade flooring may show gapping that exceeds 0.031" when assembled.

3. The relationship between wood grade and quality

Grade and quality might be two correlated terms in traditional school tests but the same does not necessarily apply to wood floors.

As a matter of fact, grade and quality should be equally taken into account in the evaluation of a product's overall value.

- Grade has to do with the aesthetics of wood floors. It is the natural appearance of all grades which vary, as they all perform well.

- Quality deals with serviceability and how the final boards are manufactured. Issues related to quality vary, including stain color variations, finish imperfections, and milling defects.

To put it simply, a high-grade wood does not necessarily promise a floor's long-term durability and value. On one hand, the manufacturing of a wood floor with high grade like Clear or Select and Better grade may include certain defects that would affect the flooring's quality. Thus, choose a certified wood flooring board manufacturer who is an expert on the subject.

On the other hand, a lower-grade wood planks might be made with little to no defects during production, hence would be considered to have higher quality, elevating the floor's value. For instance, a Cabin-grade floor can be as structurally efficient as a floor graded as Select and Better that comes with a more rustic look and more character marks.

4. Deciding the wood grade for your flooring.

Keep in mind that even as wood is a natural material, two boards of the same grade will not look identical. It is advised to examine a large sample of the wood floor before you make any purchase so that you have an idea of an accurate perception of the differences between the wood grades.

Go for lower wood grade if you prefer your hardwood floors to have color variations and characteristics and be ready for the character each brings to the project. If you have a generous budget and prefer the more uniform colours and characteristics with less or no knots, character marks, or pinholes, buy higher wood grade for your flooring. Note that floors made of higher wood grades typically have longer boards, while lower grades of wood flooring have shorter ones.

Choosing wood for your flooring is made easier with basic knowledge of grading so you can determine the ideal material for your flooring based on personal preference, especially when combined with other main criteria – durability, stability, and quality of the flooring.

Leave Reply